Here’s how to achieve greener construction transport

Why changing the use profile of construction vehicles is important

The development, construction and ongoing operation and maintenance of a property relies on bulky, and often heavy materials, as well as labour to coordinate the assembly of all of the constituent parts.

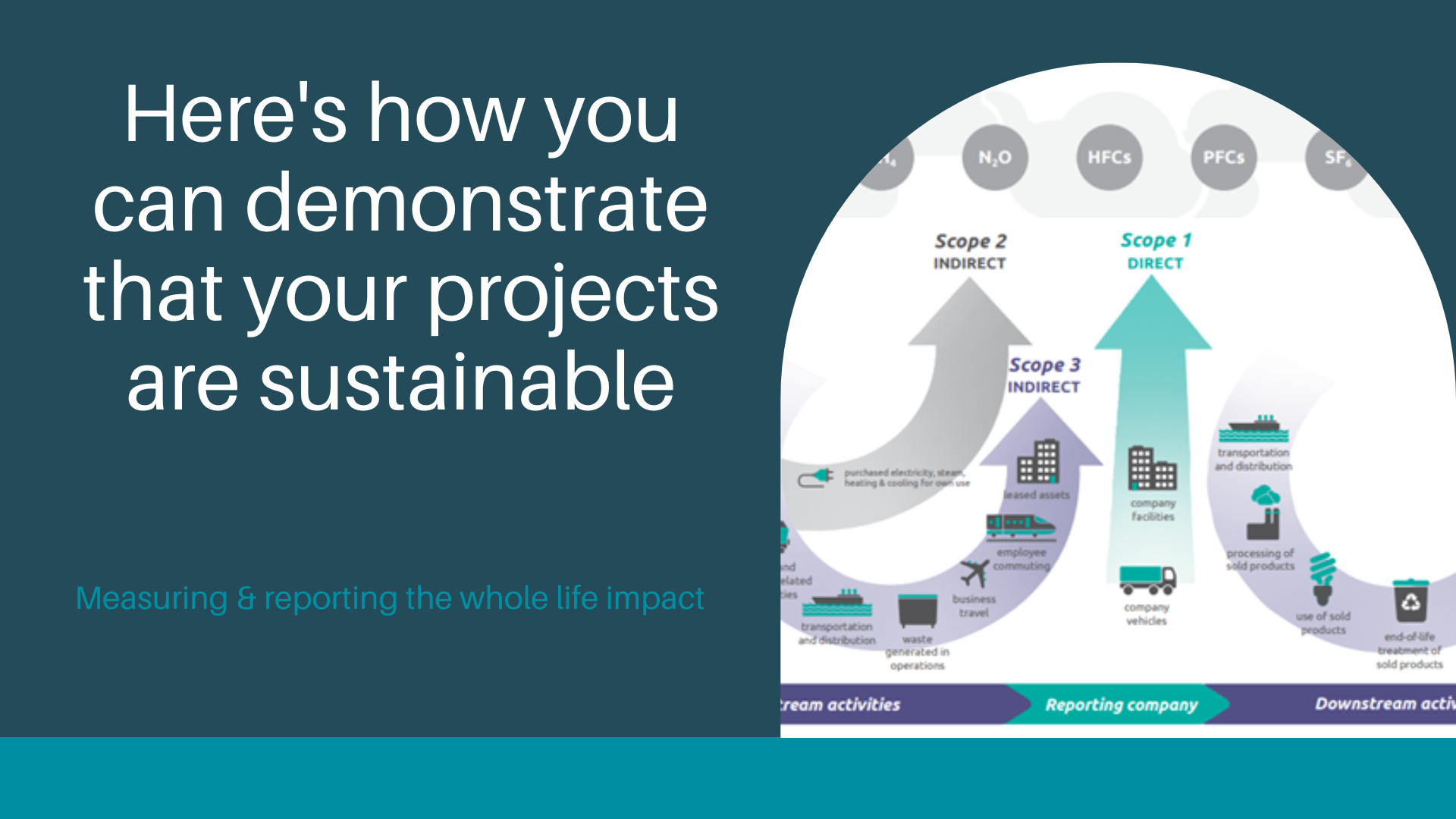

Transportation of materials (and people) in construction and maintenance is estimated to contribute a significant part of the total emissions associated with a property over the course of its whole life cycle. This can include both transportation for moving materials or people from one location to another (and ultimately to the location of the property), and the use of plant and vehicles on a site.

Transportation or plant use can be required across the whole of the value chain, whether:

- During material extraction, e.g. mining

- Transporting extracted materials to processing plants

- The movement of components to factories, for assembly

- Delivering finished materials to site

- Bringing labour to site to build the project

- On-site construction plant

- Supply of spare parts or repair labour once the site is open

- Removal of waste from site

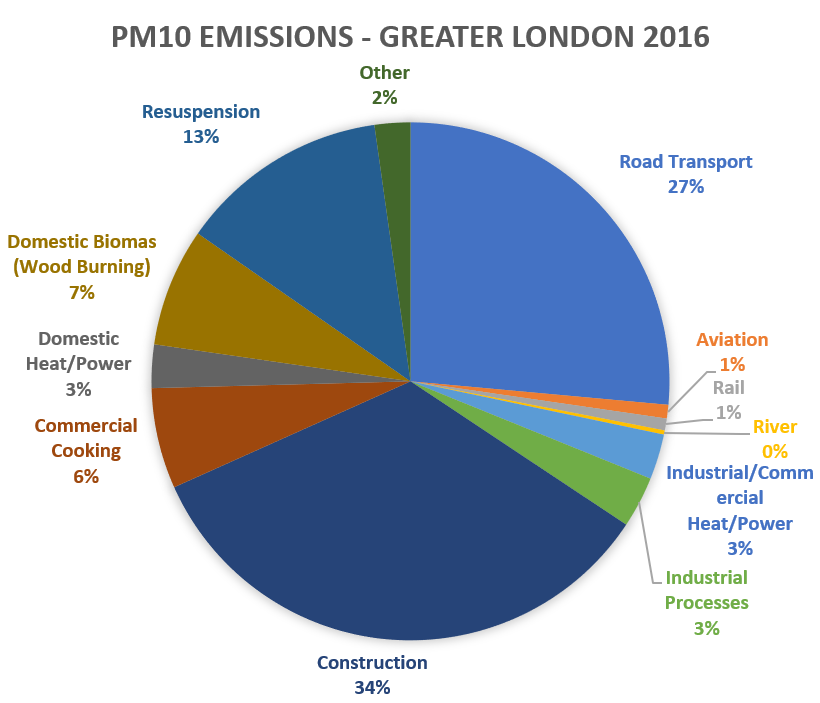

Given the bulk of many materials, such activity often demands a high payload or torque, which has traditionally been provided by fossil fuelled (and especially diesel) vehicles, which have a substantial effect on both carbon and particulate emissions.

Overall transport accounts for an estimated 8-10% of all UK carbon emissions. Of this, road transport and particularly HGVs make up around 17% of GHG emissions and 21% of nitrous emissions despite accounting for only around 5% of vehicle miles.

Public awareness of increasingly problematic air pollution, both in terms of personal comfort and the financial and resource burdens of respiratory conditions on the public health system are further reasons to consider how to make construction transport and plant use more sustainable.

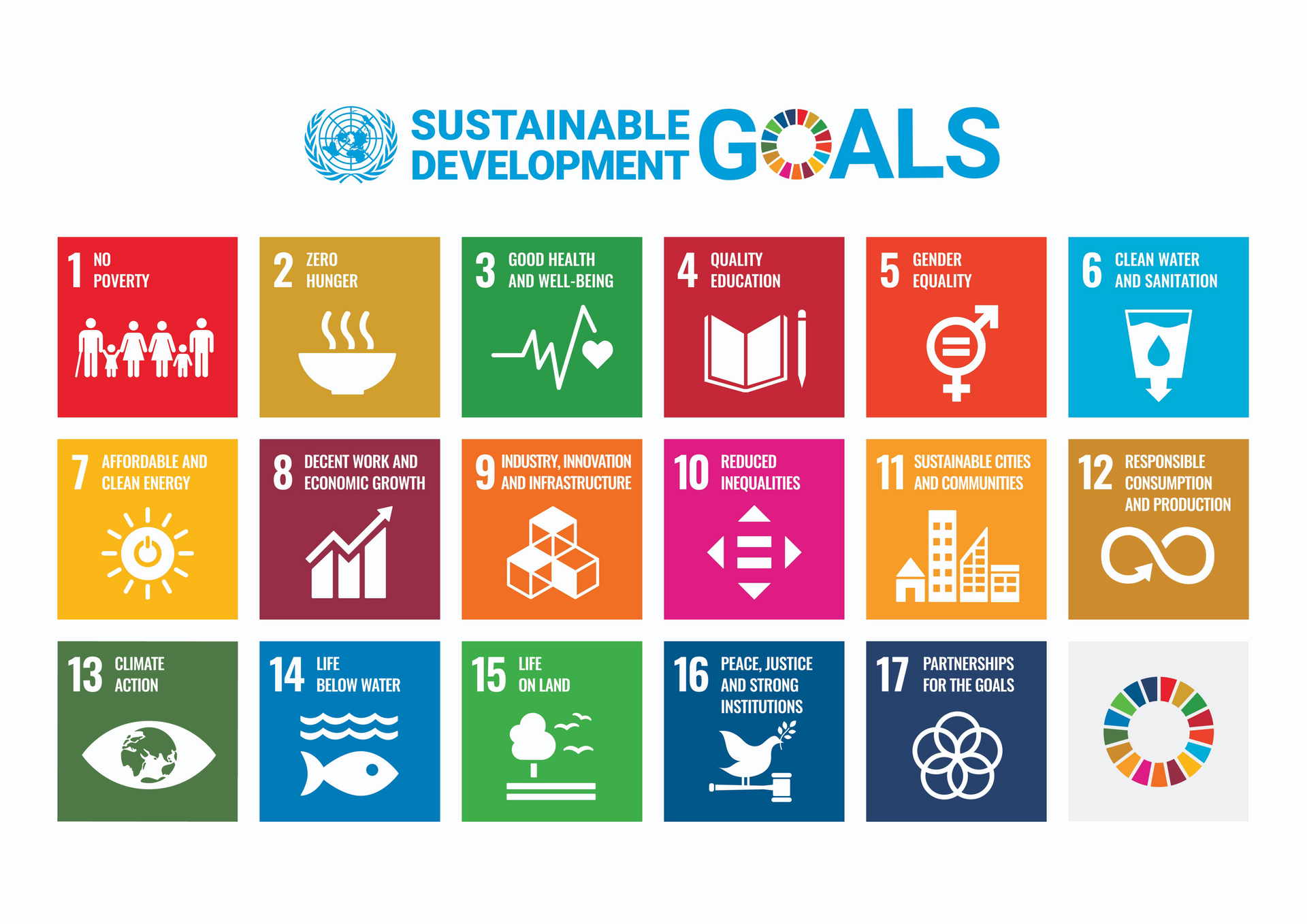

While the de-carbonisation of the transport sector is not directly within the control of site operators and developers, there are methods that can be employed to reduce the impact of your supply chain’s transportation and plant use on the environment.

Most construction industry sub-sectors are already working on net zero roadmaps to identify how to reduce their carbon impact. Invariably this includes looking at how to reduce vehicle emissions, so many options ae emerging to achieve this.

What you can start to do now

The means for reducing construction transport and plant emissions can be addressed by considering a hierarchy of approaches:

- Reduce volumes (or the mass) of materials required

- Minimise the distance travelled

- Coordinate a lower number of journeys to the site

- Clever design to minimise on site plant use

- Seek the greenest modes of transport or plant

Some examples of how to achieve these aims might be:

Material / Waste reduction

Well thought through design can affect not only the amount of new materials being brought to site, but also reduced waste means less transport away from a site. Re-use or re-purposing of existing materials can reduce the need for new materials. Off-site fabrication can restrict the waste generated to a manufacturing facility where it may be more easily recycled. Careful ordering of pre-cut lengths of material can avoid offcuts. On site treatment or processing could retain material on site that might previously have been removed as waste. As an example, on site crushing of concrete for use as aggregate, or in situ remediation of contaminated soil.

Reduction in distance travelled

Locally sourcing materials where possible can reduce the “material-miles” travelled. There may be more scope for more localised deliveries to be performed by smaller payload vehicles. As such more sustainable forms of transport such as lower emission EV delivery vehicles might be utilised.

Construction Consolidation Centres or materials hubs

These can also reduce overall transport miles and avoid having to store and move materials around site, by providing a central location for materials to be stored until they are required, when they can be transported in an optimised delivery at a time that suits the contractor.

Accurate and smart on-site planning

Enables deliveries to be made just in time, avoiding abortive visits and redeliveries, allowing materials to be offloaded and placed or used in the correct site location immediately and can also allow the timing of deliveries to be scheduled for least busy periods on the transport route, avoiding congestion and vehicle idling.

On-site efficiency

The less on-site assembly required, the less need there may be for on-site plant use. Lower carbon plant options are increasingly becoming available with power trains utilising both EV or fuel cell becoming more widely available, as well as an increasing availability of combustion engines which can run on either hydrogen or vegetable oil derived fuels. Many contractors are now investing in these options which most major plant and vehicle manufacturers, and plant hire companies, are committing to. Larger contractors have also been challenged to develop at least one zero diesel site by the end of 2023.

Using Low or Zero carbon vehicles for labour

Lower carbon vehicles such as EV are being adopted by fleets, and the sharing of transport (car share or minibus from a central pick-up location) reduces the overall number of vehicles used. This can also help with parking on site and neighbourly relations. As more lower carbon vehicles are used, contractors may need to consider provision of charging facilities on site.

These are just the first options for consideration.

Please contact us for a more comprehensive discussion about how we can support your journey to net zero.

+44 01993 883 974

info@evenloderoadside.com

Evenlode Roadside is a trading name of:

Reese Procurement Limited

Registered Address

5 Minton Place

Victoria Road

Bicester, Oxon

OX26 6QB