Selection & Sourcing of Lower Impact construction materials

Selection & Sourcing of Lower Impact construction materials

With the growing interest in sustainability, more attention is now being paid to the carbon impacts of constructing and refurbishing sites.

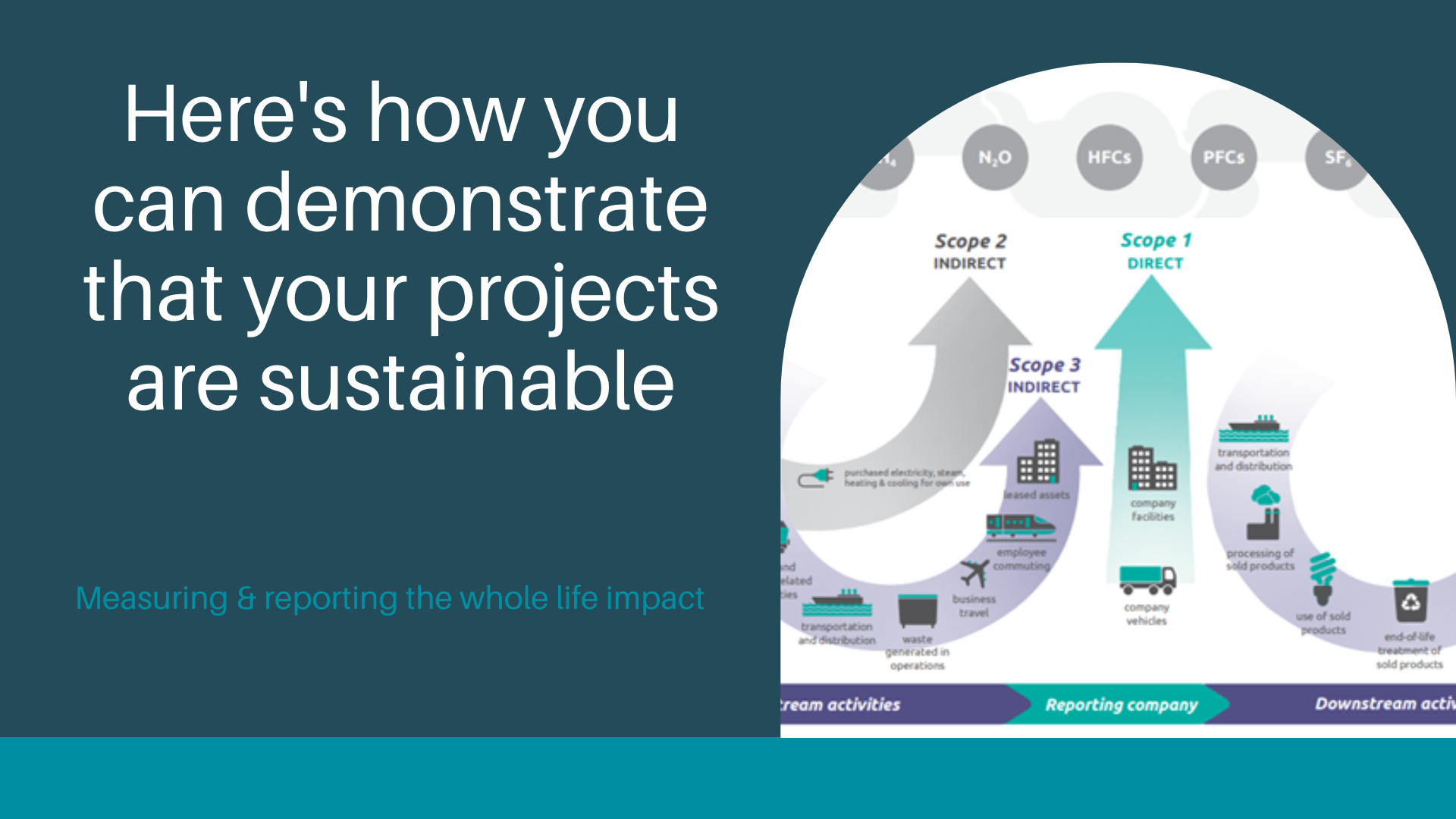

In our earlier article about design, we introduced the concept of whole life carbon, which includes both embodied carbon and operational carbon. As a reminder, Embodied Carbon includes all of the carbon impact arising from obtaining the material.

All assets are constructed using materials which have to be extracted or grown, transported to a factory to be processed, transported again to be transformed into a building product, transported to site, and erected into the asset. The combination of the above-mentioned processes result in the emission of greenhouse gases, by way of the fuel consumed for transport, and the extraction and manufacturing processes.

In this article we will focus on the impact of construction materials.

What else is important to consider?

The impact a material has on the planet is not just limited to the amount of greenhouse gases emitted as part of its production and delivery.

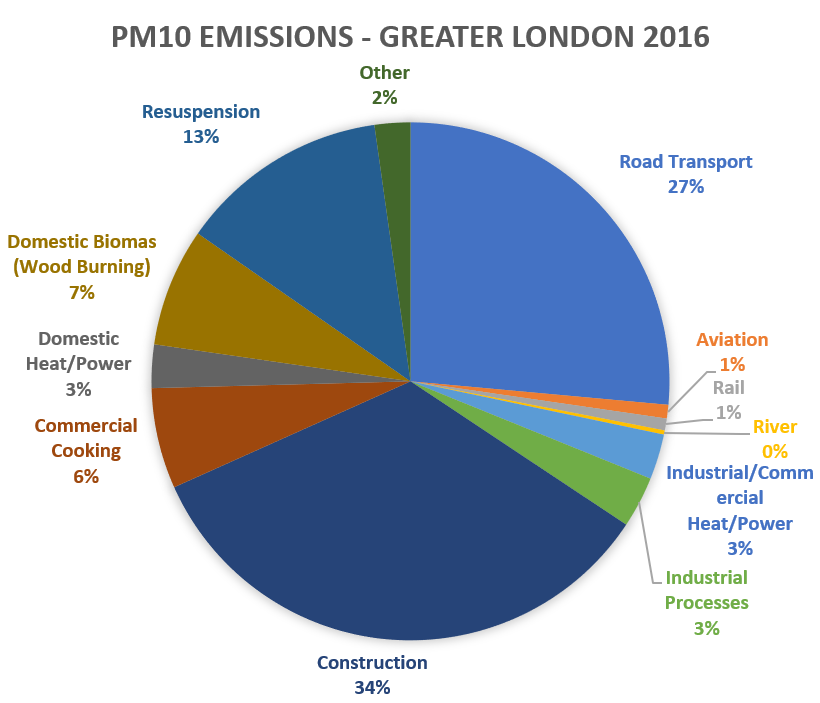

As well as the physical impact on air quality through emissions and global warming, there are also many other considerations which will also need to be addressed in the coming years and decades.

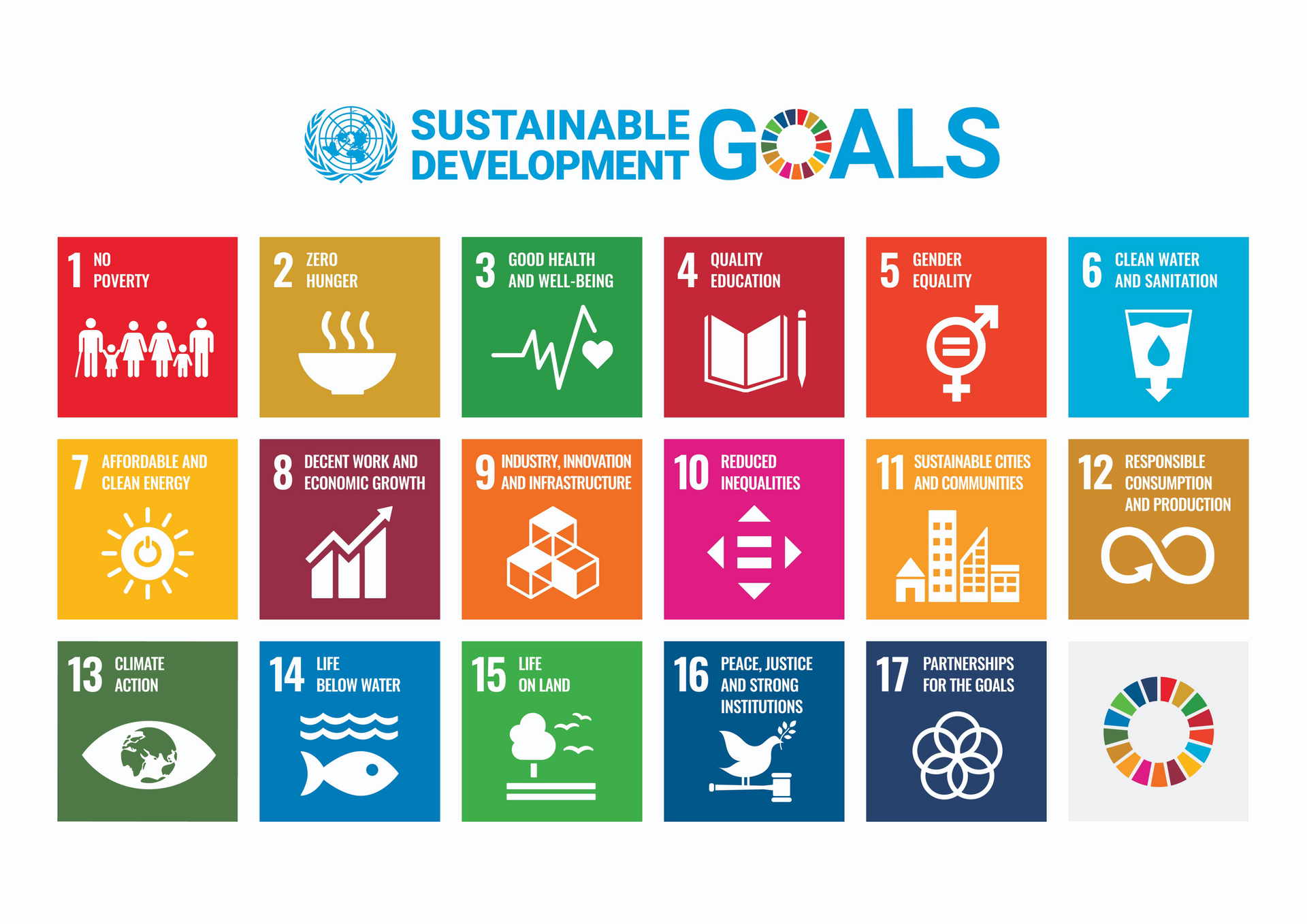

These include both ethical and social considerations, such as the impact on the people and local communities where the materials have come from, and also matters of modern-day slavery. We will look at these issues in a separate future article.

There are also other environmental impacts which should be considered, including other forms of air and water pollution, soil pollution, land degradation and waste management. In many parts of the world issues such as deforestation and loss of habitat and biodiversity are also relevant. We will look at these issues in more detail in a future article.

It goes without saying that sourcing materials that arise from nearby your site or re-using the materials already on your site will clearly have an impact on the amount of transportation emissions included in the embodied carbon of a material.

What are key material producers already doing?

Not all materials are created equally, and in the same way, some common construction materials have a significantly higher carbon impact than others. Two of the most common construction materials include steel and concrete, and for very good structural reasons.

Unfortunately, both of these materials account for significant amounts of not just construction emissions but global emissions as a whole. Concrete for example is said to account for at least 8% of all global emissions. Worldwide, 30 billion tonnes of concrete is used each year. On a per capita basis, that is 3 times as much as 40 years ago — and the demand for concrete is growing and is likely to continue to grow as the new infrastructure that is required to decarbonise other sectors gets constructed.

The steel industry is also one of the three biggest global carbon emitters. According to a 2018 report, every tonne of steel produced in 2018 emitted on average 1.85 tons of carbon dioxide, equating to about another 8% of global carbon dioxide emissions.

It is highly likely that the demand for both of these key construction products will continue to rise in the next decade at least.

To the credit of both the concrete and steel industry they are both already well on the way to coming up with plans to decarbonise their industries over the next 20 years, with most of the major manufacturers in both sectors having published detailed publicly available plans for how they will move to achieve this. Lower carbon products are already becoming available.

Other common construction material sectors are also making great strides towards identifying how to reduce their impact too, and of course some materials will inherently be more environmentally friendly in the first place.

Some approaches to reducing the impact of materials

Designing out carbon, by employing capable and motivated designers and engineers who can specify alternate materials is the first obvious step, where technical standards might allow for suitable material substitution, or clever re-design. Commercial expectations and models may need re-imagining in some cases to incentivise and reward measurable carbon reductions.

Specifying low or lower carbon materials (especially concrete and steel) is likely to have the biggest impact on most construction projects, but in the short term such an approach might also have an impact on the build cost.

Specify that materials should have an EPD (Environmental Product Declaration) which is defined by ISO as a declaration that "quantifies environmental information on the life cycle of a product to enable comparisons.

PAS2080 compliance. PAS 2080 is a standard for managing carbon in building and infrastructure. We will look more closely at the selection of contractors in another article.

Consider Modern Methods of Construction which can allow for more control of emissions in a specified (typically offsite) environment, improve onsite logistics, reduce waste and transport to site.

Some ways you can challenge yourself to make your projects more sustainable

So what things can you consider doing now, for your developments?

You could:

- Investigate the impact that specifying and / or trialing an alternative low carbon product or material on a project

- Identify relevant embodied carbon asset standards and compare your design’s performance against these

- Set an embodied carbon baseline and structure your commercial arrangements to incentivise and reward designers (or design & build contractors) who exceed these